Features & Benefits

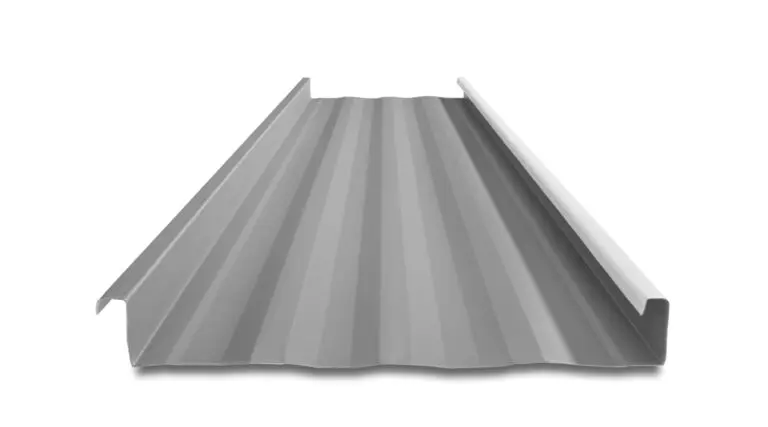

- 12″, 14″, 16″ and 18″ options available

- 24 and 22 Tru-Gauge™ and .032″ and .040″ Aluminum

- Zinc Coil (inquire for thickness)

- Floating clip system: allows for expansion/contraction of panels in longer lengths

- 2″ vertical rib, factory notching available

- ½:12 minimum pitch recommended (for lower pitches, please inquire)

- On-site roll forming available for longer panels

- Factory injected Butyl sealant available

- Concealed fasteners: fasteners cannot leak

- Weathertightness warranty available (Contact TMP representative for details)

- MS-200™ FM Approvals Class: 4471

- OverEZee retro-fit system available

- Panel options: Striations, Accent Ribs, Flat Pan

- Manufactured in Salem OR, Riverside CA & Sacramento CA

DI SEAMER Standard Rental Guidelines: click here

• 180 degree seams are not considered an architectural detail. The detail improves the weather tightness and wind uplift capabilities of the panel system, but will show stress and waviness in the seam. The detail is recommended for slopes less than 3/12, roof areas not easily viewed from the ground, and for high wind areas. For additional information, contact a TMP representative and DI Seamers for support and information about the proper use of seaming tools.